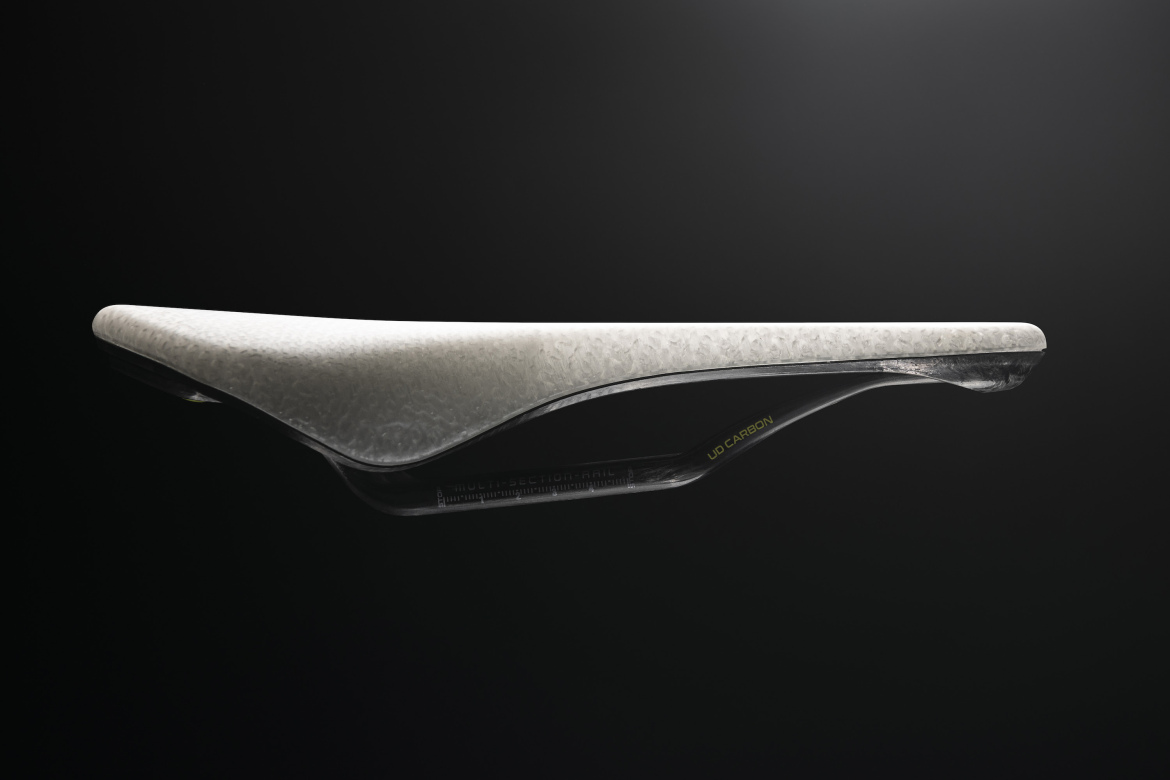

3D-printed bike saddles are nothing new, with models from Specialized, fizik, and even Rockbros becoming popular with riders. One thing most of these saddles have in common is that they don’t include a traditional cover because of… reasons. The new Repente Nomad 3D is shaking things up by adding a cover to their 3D-printed padding, and they have their reasons too. Who is right? It’s hard to say.

A cover protects the lattice structure inside

3D-printed saddles make use of a polymer material to create a honeycomb-like lattice structure that’s designed to optimize comfort. The result is a surface that’s firm where it needs to be, and soft where you want it to be. The problem is that the thin polymer strands are prone to snags and tears, especially on the trail, and by adding a cover, the lattice structure is better protected.

Another issue that mountain bikers may encounter is mud and dirt accumulating within the nooks and crannies of the exposed 3D-printed material. As grit works its way into the structure it can slowly wear down the structure over time, not to mention it makes the saddle heavier bit by bit.

Specialized has a couple different 3D-printed saddles to choose from, and one of them that Singletracks has tested — the Power Expert with Mirror — has a four-way stretch cover to keep debris out for mountain biking and gravel riding. However, unlike the Repente Nomad 3D, the Power Expert with Mirror surrounds 3D printed inserts with traditional foam padding rather than utilizing a multi-zone 3D matrix throughout.

But, a cover can interfere with the movement of the lattice structure

Adding a cover to a 3D-printed saddle has the potential to interfere with how the padding material behaves, which is one reason other manufacturers don’t use a cover. Repente’s cover is made with TPU, the same thin, plastic material found in TPU tire tubes. Presumably this smooth and slippery material allows the underlying structure to act somewhat independently of the cover, though clearly the cover serves to compress the edges of the saddle padding even if pressure is applied closer to the middle of the saddle.

Some saddles are grippier than others

You may not realize it, but saddle covers are designed to deliver a certain amount of grip to your shorts. Too much grip, and it can be difficult to reposition yourself for a descent; too little, you’re sliding off the back on the climbs. Some riders complain that exposed 3D lattice structures are too grippy, snagging shorts at the most inopportune times. This is partly because of the shape, but also because of the polymer material that’s used.

Repente says “the smooth and homogeneous surface makes the saddle more compact and resistant and does not hinder the cyclist’s movement.”

A cover adds weight and cost

Though mountain bikers have a few options when it comes to 3D-printed saddles, the earliest models were designed for road riding where weight is king. 3D-printed saddles are generally pretty lightweight, but they’re not the most lightweight option, and a cover simply adds to the weight.

The Repente Nomad 3D saddle with carbon rails weighs 180g compared to a saddle like the PRO Stealth Team Saddle which weighs just 160g. Of course you could just do away with the saddle padding and cover entirely, like this 85g torture device, but most of us will want something more comfortable.

Another issue is that 3D printed saddles are generally more expensive than traditional foam padded seats (the Rockbros model notwithstanding). With a cover, there’s an additional cost for the material and also the labor involved in cutting and attaching it, which increases the price. The Repente Nomad 3D costs $410.31 USD which is cheaper than the S-Works Romin EVO with Mirror, but more than the fizik Vento Argo R3 Adaptive saddle.

Is it really a 3D saddle if you can’t see the structure?

Of course it is. However, perhaps the real reason we haven’t seen many 3D-printed saddles with a cover is that a cover hides all the high-tech goodness inside. Repente gives a nod to this with their choice of a semi-transparent cover so you can see the honeycomb structure within.

The Repente Nomad 3D isn’t just designed for road biking, so a cover makes sense to keep the dirt out and also play nice with baggy shorts. Pairing the comfort of 3D padding with the durability of a cover should make for a winning combination.

0 Comments