Pearl iZUMi relocated to a new building in Louisville, CO about five years ago. Previously they were housed in a shared, bland building down the street from their current spot.

With the move came an opportunity to develop a building that was in line with the brand’s ethos and desire to move in a more sustainable and environmentally-friendly direction.

We got a chance to check out the building, and to take a better look at Pearl iZUMi’s new brand vision, and how product development at the company works.

The surfaces, inside and out, are as natural as can be. The wood on the exterior is sourced from used, Wyoming highway snow fencing.

The building’s shell is made from recycled steel. It blends in with the red rocks of Colorado’s front range and doesn’t call for an unnecessary finish like paint.

Most of the interior is raw, minimalist, and unfinished, also. The walls are plywood, and unpainted to prevent waste. Inside of the walls are thick, insulated panels, which make the building energy efficient.

Pictured above is the brand’s showroom, which displays this year’s apparel, along with some offerings from their parent company, Shimano.

Pearl iZUMi’s origins date back to the middle of the 19th century in Japan. The name translates to “fountain of pearls.” Pearl iZUMi drafted a new vision for the brand this year, summed up with the simple slogan, “here we go.” They’ve moved away from competitive vibes and toward a vision that is based around the experience of riding. Pearl iZUMi is sponsoring new athletes that project inclusivity and adventure, like Lael Wilcox, Syd Schulz, and Macky Franklin.

The new apparel line is subtle, with more earth-based tones. The mountain bike clothing is fitted, but not too tight or racy, and should check all the boxes for everyday trail riders.

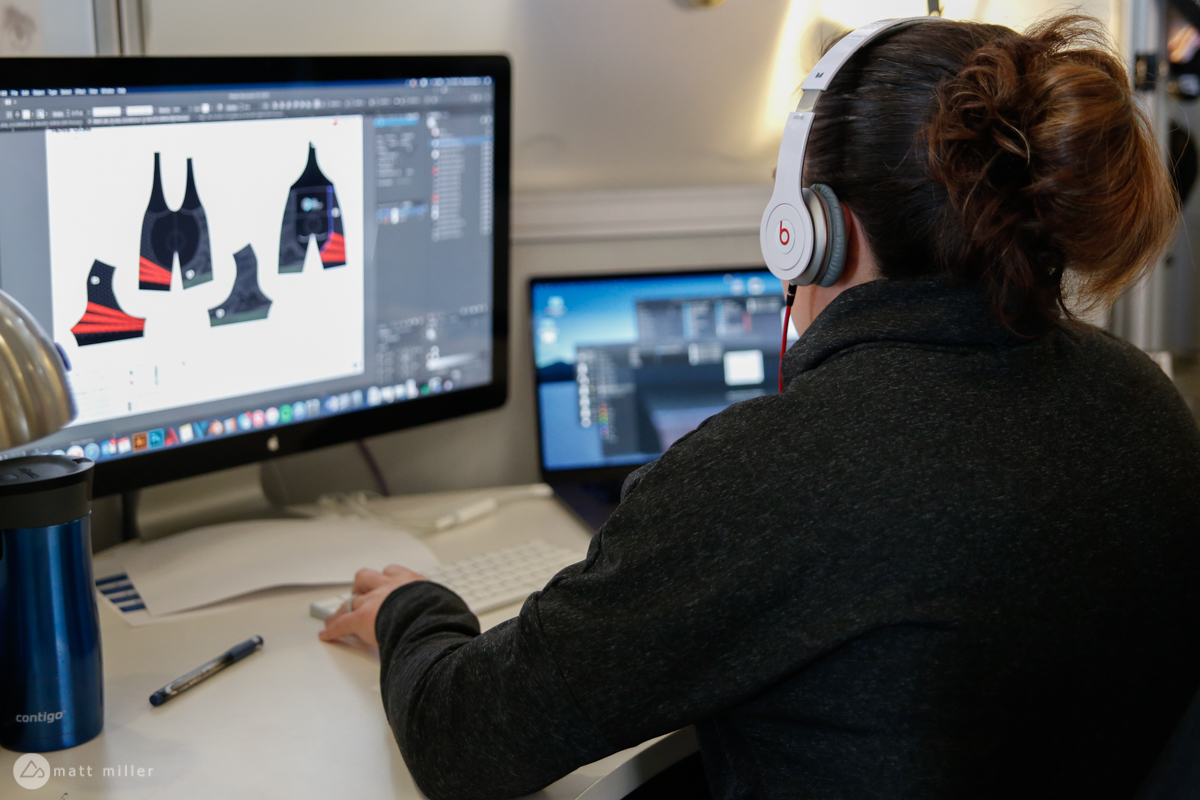

Apparel designing takes place in an open workspace. Windows dominate the walls for an abundance of natural light, and the space is open to maximize the flow of energy and ideas. In all, there are only about four private offices in the 55,000-square-foot building.

Apparel design begins at the computer. Andrew Hammond, Pearl iZUMi’s marketing representative, says that the entire process for one piece of apparel — like a pair of shorts or a jersey — from design, to prototype, to fit, to production, costs about $10,000.

Prototyping makes its next step at the station shown above. A paper pattern is cut out and laid on the fabric for the individual panels of a prototype garment. Then, they are stitched together.

Pearl iZUMi partnered with Renewal Workshop for 2019. Returns and product warranties can be repaired and turned around so that they don’t end up as waste.

Although final Pearl iZUMi apparel manufacturing takes place in various Asian and European factories, initial prototypes start here. Men Nguyen, shown above, is working on a prototype for a jersey that isn’t set to hit the market until sometime in 2020.

Prototyping at the factory allows Pearl iZUMi try out a new jersey with say, several different collars, so athletes and testers can see which one has the best style or function.

Pearl iZUMi closely watches trends in the cycling industry to predict styles for apparel lines in the coming years. The brand says that it’s also helpful to watch how trends change in the ski industry, since trends in the bike industry often run in parallel.

The materials testing lab sits in a corner of the building. Apparel is tested for its durability, stretch, abrasion resistance, snag resistance, and water resistance.

The Atlas Launder-ometer can be loaded with fabric samples to simulate wash-cycle wear. One cycle in here can simulate 25 real world wash cycles at once. The colorfastness of material is tested to see how fast the apparel colors will fade.

The inside of the machine can be loaded with rubber balls or steel bearings to accelerate colorfastness testing.

A wall of these small fabric swatches in different colors and materials is available in the materials testing lab for evaluation and prototyping.

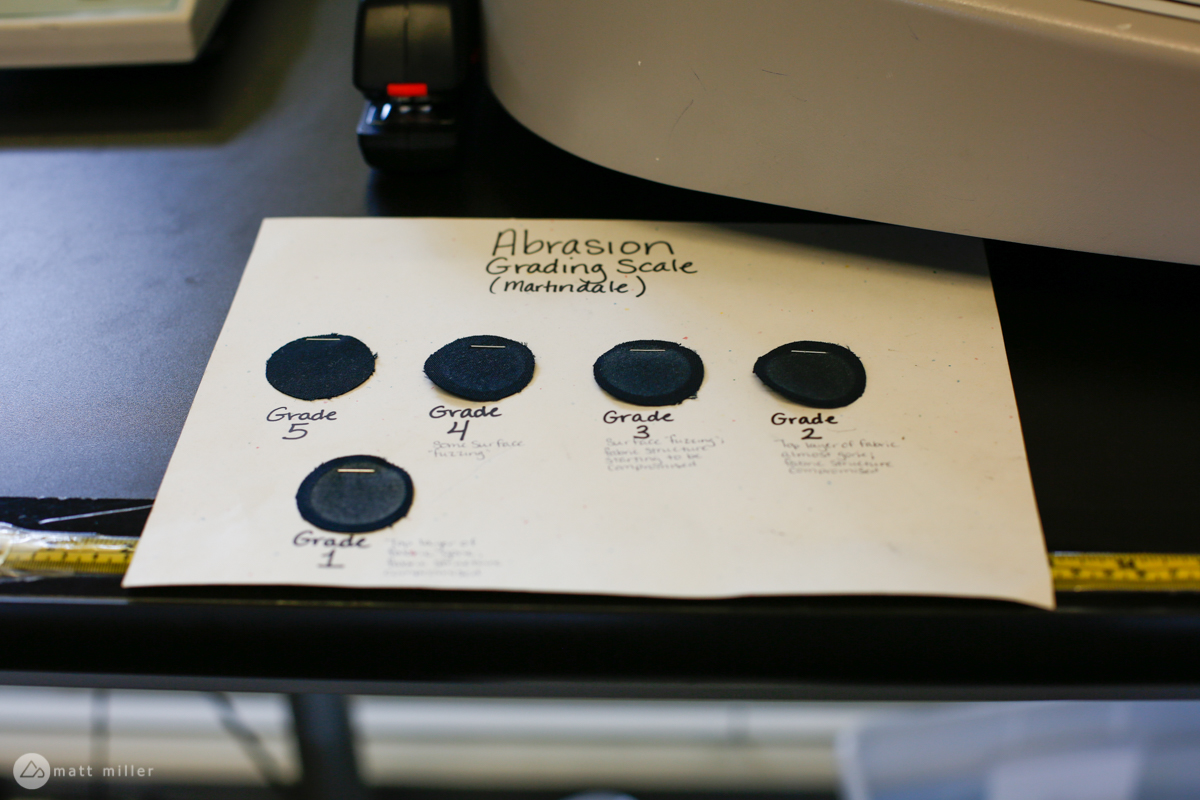

Clothing is of course tested for abrasion resistance as well. Pearl iZUMi requires all of their clothing to meet a grade 4, with minimal abrasion wear, on the Martindale scale before it goes into final production.

The Martindale, along with most of the testing methods used in the lab, are industry standards, and Pearl iZUMi says that they submit their product to longer test durations than a lot of other brands.

The abrasion test cycle places fabric under a cylinder and rotates it around another pad to see how rubbing will affect the material.

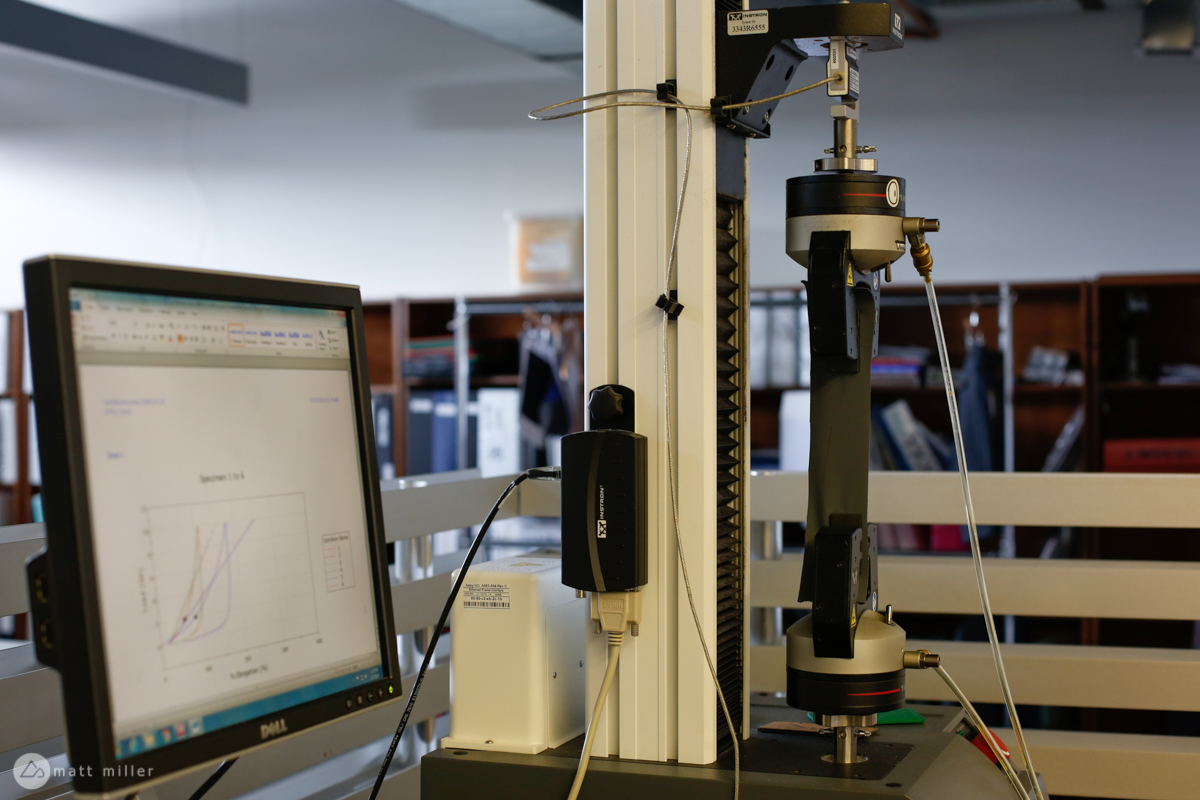

Strength and tensile testing is another way to assure product quality. Machines like this test the integrity of a product’s seams, or a fabric’s ability to stretch, or when it will shear or tear. Sensors collect relevant data, like how much force it took to rupture the material.

Lastly, we enter a fabric’s remaining room of fear in the testing lab, which houses the Orbitor. The Orbitor has a SnagPod and another box that tests for pilling.

Fabric samples are cut out and placed around this spool.

This cork-lined box tests for pilling.

And, the inside of the SnagPod is lined with rows of tiny metal blades.

Then the cycles begin. Testing in the Orbitor can last for several hours, while the fabric samples bounce around against cork or small blades.

The final step in the Pearl iZUMi testing process involves humans. Testers are brought into the building and set up on this test bike. Prototypes are tested for how well they fit. The shoulders on jerseys shouldn’t feel tight when someone is in a riding position. Shorts should form to an athlete’s hips when pedaling, so that they aren’t battling the tightness of the material, and so on.

Pearl iZUMi says that because of the extensive testing conducted on apparel in the prototype process, they see a fairly low warranty rate. Clothing lasts longer than expected, which makes most mountain bikers happy to get their money’s worth. Clothes shopping for mountain biking can often be expensive, but it’s nice to know that brands like Pearl iZUMi test their products this extensively, and aren’t just trying to latch onto the latest trends in color or fit.