TRP recently announced a partnership with Sinter to expand distribution of Sinter’s Smart Bedding Machine for disc brakes. To be honest, I didn’t even know such a machine existed, and now I kinda want one for myself. Or at the very least, I’d be stoked to use one at my local bike shop.

Bedding in disc brakes is a science

By now, you’ve probably heard that properly bedding in your disc brakes is the key to maximizing performance. Bedding brakes involves transferring and depositing material from fresh pads onto the rotors. Brake brand Magura explains it this way in their technical documents:

During the break-in phase, the smallest imperfections are ironed out to create the optimal friction surface between the pads and rotors. Additionally, bedding-in your pads removes any residue of the manufacturing process from the brake pads. Optimal performance and durability are only reached after the break-in phase has been completed and both the pad and rotor surfaces are fully in tune.

To ensure an even application of the pad material, it’s important to conduct the bed-in procedure while riding on a smooth surface and to apply the brakes in an even, consistent manner to avoid depositing too much — or too little — material in a single spot on the rotor.

“Bedding in disc brakes has traditionally required manual labor, test rides, and exposure to inconsistent variables like rider input, terrain, and weather,” TRP writes in a press release announcing the company’s partnership with Sinter. “The TRP powered by Sinter Smart Bedding Machine simulates real-world braking conditions in a controlled environment, delivering perfect pad-to-rotor contact in minutes—with no test rides, no noise, and no surprises.”

The brake bedding machine

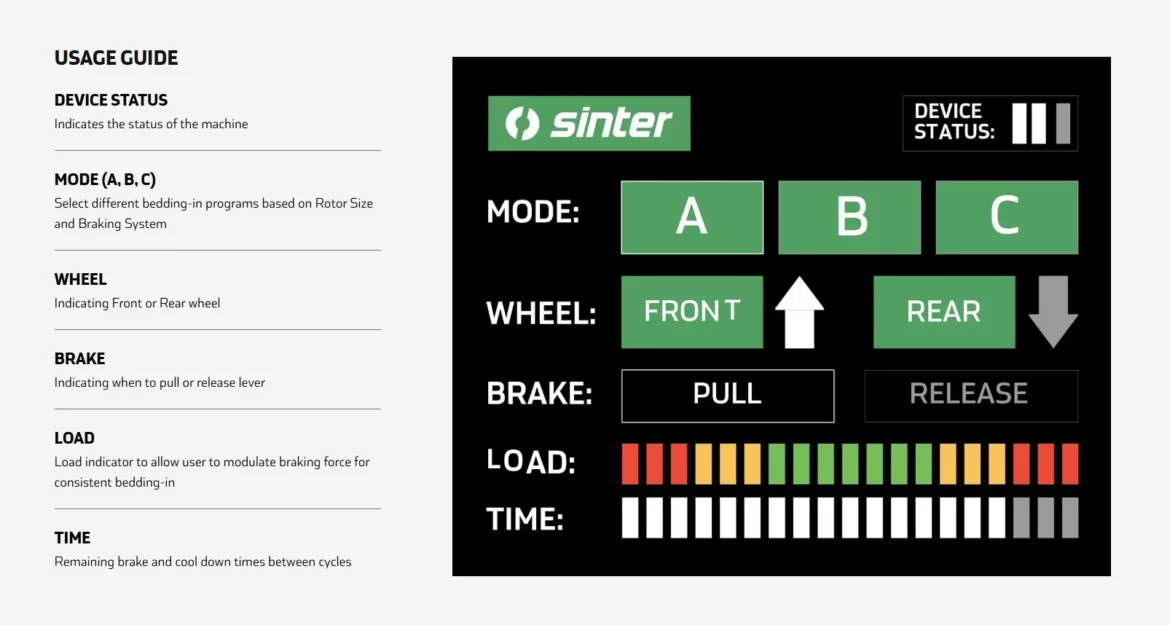

The TRP Powered by Sinter Smart Bedding Machine spins a bike’s wheel at a prescribed speed and indicates when the operator should pull or release the brake lever. There are different modes depending on the brake type and rotor size, and the TRP website suggests the Smart Bedding Machine works with a “wide variety of different brake pads, brake systems and rotors on the market,” which presumably also includes brakes from brands other than TRP.

Priced at $2,750 in the USA, the Smart Bedding Machine is targeted toward original equipment manufacturers (OEMs) and bike shops. Clearly, this isn’t a machine to be used by an individual just once or twice a season to break in a new set of pads or rotors.

The rollers are designed to fit wheels between 20″ and 29″ in diameter and tires between one and three inches wide. The machine weighs about 50lb and spins wheels at 14.9mph. Singletracks has reached out to TRP to find out how long it takes to bed in a single brake, but did not hear back as of press time.

Not everyone agrees on a “proper” brake bedding procedure

Though most mechanics and experts agree on the basics when it comes to a proper brake bedding procedure, Singletracks has learned that there are some differences of opinion.

Brake manufacturers recommend pulling and releasing the brakes between 20 and 50 times to bed them in, which is a wide range. Most recommend slowing from a speed of about 15mph — which matches the speed of the Smart Bedding Machine — while others recommend a speed of 19mph.

Calvin Jones from Park Tool recommends spraying the pads with water in between pulls to form a slurry-like paste with the pad material, which is said to improve deposition. Hayes has previously made a similar recommendation for bedding in their brakes.

“We designed the machine to make brake setup effortless, repeatable, and workshop-friendly,” said Sven Curila, Technical Director at Sinter.

“This is about raising the standard of brake performance across the board,” said Nathan Silberman, US Marketing Coordinator at TRP. “From OEM builds to boutique bike shops, we’re helping partners deliver better brakes, faster, with fewer headaches.”

3 Comments

Sep 24, 2025

Sep 24, 2025

Sep 24, 2025

We'll see if my LBS springs for one of these brake bedders.